IPC - Standards for the acceptance of electronic system assemblies and their design

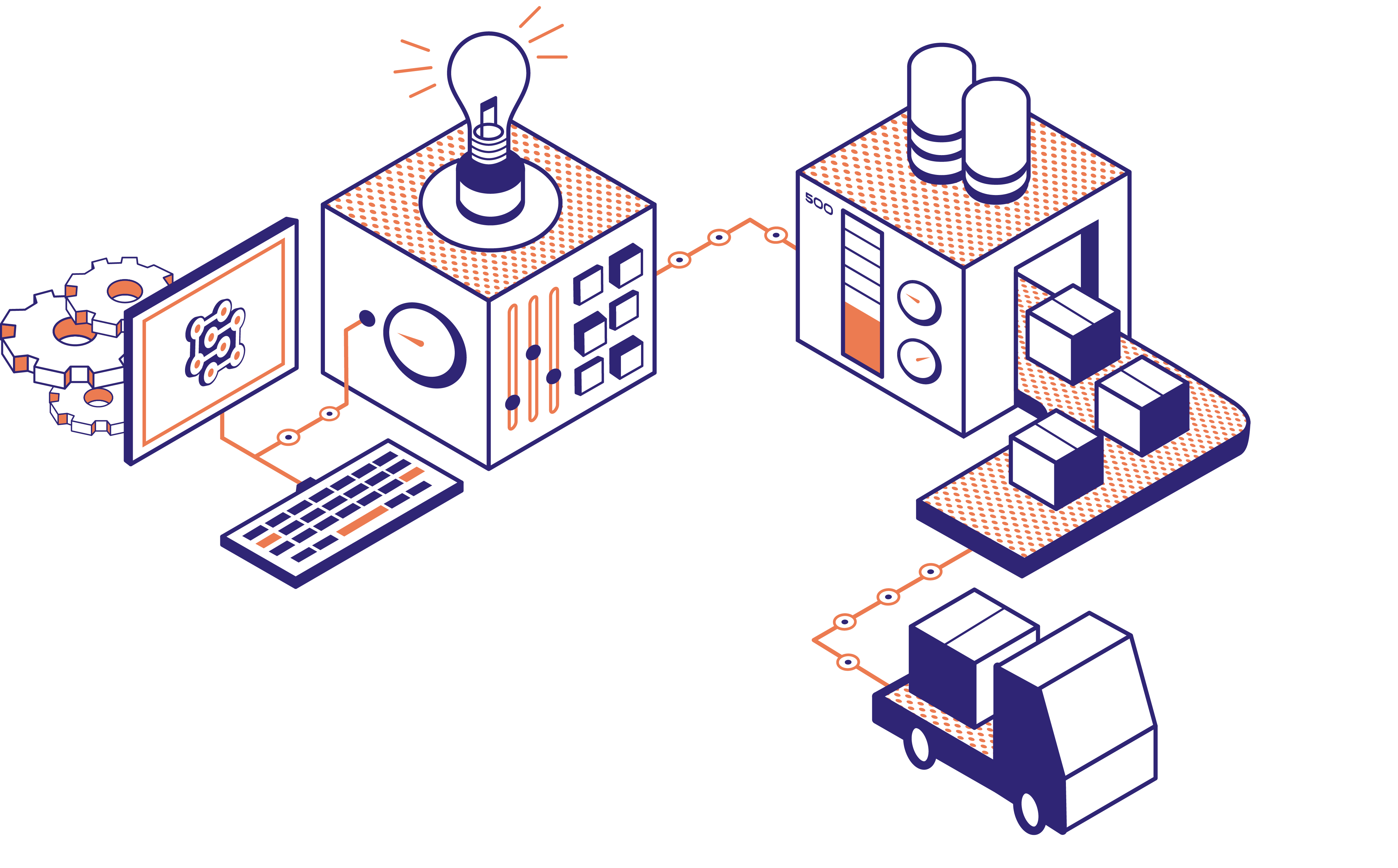

Discover the electronics factory of the future

EMSFACTORY is the first fully web-enabled electronics factory.

- SHORT & CONTROLLED LEAD TIME

a 100% online manufacturing process

Competitions and prizes obtained

specialised offers

All components are counted and repackaged for placement by an SMD Pick & Place machine.

All components are counted and repackaged for placement by an SMD Pick & Place machine.

Our precision robots place your components from the smallest (01005) to the largest (70x70mm).

Our precision robots place your components from the smallest (01005) to the largest (70x70mm).

The boards pass through the convection oven which respects a JEDEC temperature profile, and is checked daily by a profiler.

The boards pass through the convection oven which respects a JEDEC temperature profile, and is checked daily by a profiler.

The AOI machine takes HD photos of the board, and checks all SMD assembly acceptance criteria.

The AOI machine takes HD photos of the board, and checks all SMD assembly acceptance criteria.

We carry out X-rays of the most complex assemblies to be controlled (BGA, LGA, etc.).

We carry out X-rays of the most complex assemblies to be controlled (BGA, LGA, etc.).

The pins of the component are bent and cut then the components are inserted on the PCB.

The pins of the component are bent and cut then the components are inserted on the PCB.

The assembly of through-hole components is checked according to the criteria of IPC standards.

The assembly of through-hole components is checked according to the criteria of IPC standards.

A report is automatically generated and can be downloaded to your web account containing all the information related to the manufacturing process.

A report is automatically generated and can be downloaded to your web account containing all the information related to the manufacturing process.

Your order is packed in an antistatic bag and sent by express carrier.

Your order is packed in an antistatic bag and sent by express carrier.

All manufacturing constraints are checked one by one

All manufacturing constraints are checked one by one

The paneling of your PCBs is carried out according to your instructions entered online or your files

The paneling of your PCBs is carried out according to your instructions entered online or your files

The 30 steps min. manufacturing processes are launched: cutting, drilling, metallization, lamination, exposure, development, etc.

The 30 steps min. manufacturing processes are launched: cutting, drilling, metallization, lamination, exposure, development, etc.

All tracks are electrically tested to verify good conduction and the absence of short circuits

All tracks are electrically tested to verify good conduction and the absence of short circuits

The quality of varnish finish and marking are checked as well as the dimensions of the PCBs

The quality of varnish finish and marking are checked as well as the dimensions of the PCBs

A report is automatically generated and can be downloaded from your web account containing all the information related to manufacturing.

A report is automatically generated and can be downloaded from your web account containing all the information related to manufacturing.

Your order is packaged in an anti-static bag and shipped by express carrier.

Your order is packaged in an anti-static bag and shipped by express carrier.

Norms

EMSFACTORY complies with the main electronic standards IPC, ISO 9001, RoHS and REACH

ISO9001 - Standards defining quality management system criteria and requirements

RoHS - European Directive to limit the use of dangerous substances in electronic equipment.

REACH - European regulation to regulate the manufacture and use of certain chemical substances.