The Bill of

Material is a file that is automatically generated by your CAO software at the

end of the electronic board development step.

It is generally exported as the following formats:

- Excel sheet (.xlsx)

- Data file (.csv)

- Text file sort by separators like semicolon (.txt)

This file contain the following information :

- Quantity : it define the amount of the component that is needed to do the electronic board

- Manufacturer part reference : that is the reference of the component corresponding to the manufacturer one, it allow us to identify it, and in case of shortage, to find it on reseller websites.

- Designators : They are essential to create a link between manufacturing and assembly files. They identify to which component corresponds the reference that was previously complete

Those three elements above are essential to realise a usable Bill of Material file, but the following ones allows a more precise algorithm search of the component :

- Value : gives the component value, useful for passive ones (resistors, capacitors …)

- Description : gives the main specifications of the component (function, tolerance, casing …)

- Manufacturer : allows a faster and better algorithm search in case of specific component

- Type : match a component to its category (capacitors, resistor, coil …)

- Supplier : your preferential supplier for the component

- Supplier reference : reference that is linked with the component search on supplier database

- Cross reference : reference that match an equivalent component, it allows to find another one in case of shortage of the first one

- Maximum Voltage : gives the maximum voltage that the component allows before breaking or burning

- Maximum Current : gives the maximum current that the component allows before breaking or burning

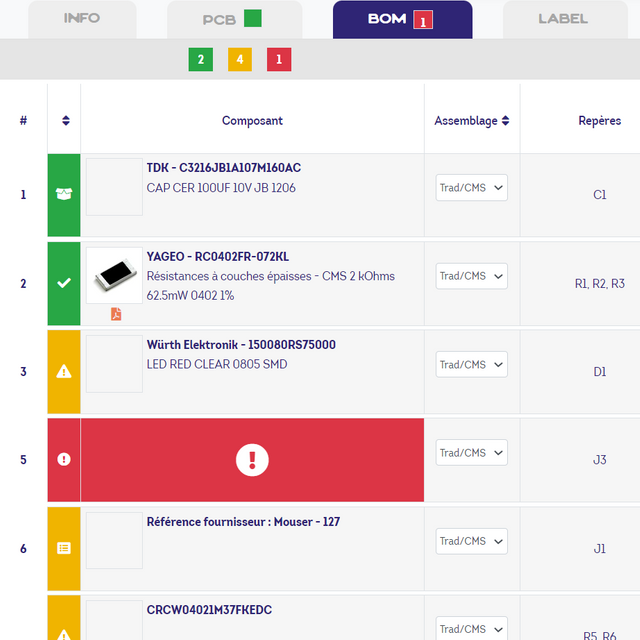

The EMS

factory website ordering interface automatically detect the components

characteristic, and use them to find them on supplier’s databases.

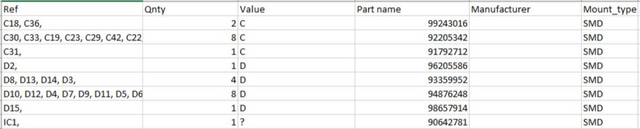

In general, an example of a not recommended Bill Of Material file is like :

In the Bill of Material file example above, there is some errors that are listed below :

- The reference of the component is not a manufacturer one

- The value of the component is not complete

- No manufacturer is given

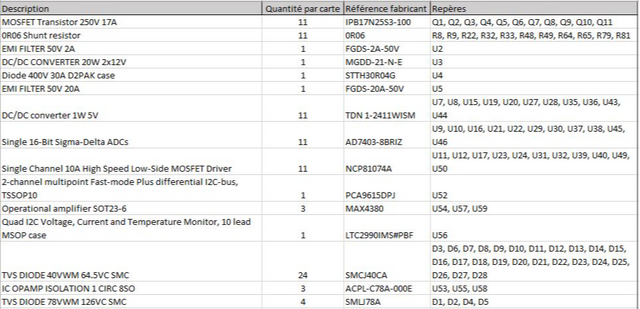

A Bill Of Material file at correct format must be like the following example :

The website

interface will ask you to select data columns (From the first to the last), and

will search the different components right after this selection.