5-6-2020

Curious and thirsty for innovation, we are starting to show off some of our suppliers who will interest our readers who are passionate about electronics!

This month we went to meet a supplier of “made-to-order” solutions for Electro-Magnetic interference (EMI) and thermal management: dB & Degrees.

We met with Hermione DEFAYE, co-founder of the company :

Could you define the work of dB & Degrees ?

“We develop and produce components and sub-assemblies to order which are integrated into the electronics or hardware of our clients, to resolve problems of EMI shielding or thermal management.“

Thermal solutions:

Screening solutions:

Hardware solutions:

A closer look at some of our solutions:

Phase Change Material

DG-PCM phase change materials are an alternative to traditional thermal grease. They are easier to handle at ambient temperature. When they are placed between a hot electronic component and a heatsink their temperature will rise. When they attain their phase change temperature, they soften and perfectly match the surface profile of the components, thus assuring minimal thermal resistance.

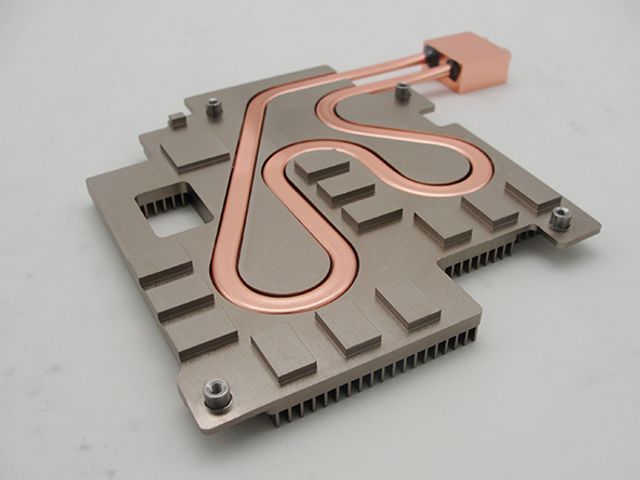

Heat Pipe

Heat pipes are the optimal technology for conducting heat away from power components while not taking much space. The purpose is to dissipate the heat in a remote heatsink or to enable the distribution of the heat in a dissipating medium. The thermal conductivity of a heat pipe can in some cases attain 100 kW/mk, compared with about 0.4 kW/mK for copper.

Thermal Pad

The addition of a silicone-based Thermal Interface Material (TIM) between an electronic component and its heatsink makes it possible to fill any empty space due to surface defects and roughness of the surfaces in contact. This reduces the thermal contact resistance and may also compensate for any height differences between the heatsinks and the components.

dB-Twin Gasket

dB-TWIN conductive seals (gaskets) are designed to provide effective IP sealing and EMI screening in the same product. They can save space in equipment because both functions are provided in a single mechanical groove. In addition, they are resistant to hostile environments (example: resistance to salt spray).

The combination by co-extrusion of loaded particles and silicone or fluorosilicone gives dB-TWIN seals excellent mechanical properties while minimising costs. By comparison with standard loaded seals, dB-TWIN seals are more flexible and thus more easily compressible in the equipment.

Who are your clients ?

“SMEs as well as large companies, also sub-contractors in France, in Europe and Internationally.“

In what situations would a client ask for your services ?

“There are two distinct situations in which our clients would need our services:

The first is when the client has not taken account of EMI and/or thermal screening in their design. These cases need urgent intervention so that the client can pass certification tests and get their products into production or pre-production in a very short time frame.

The second is a much more comfortable situation, being a collaboration at the design stage. In this case we are often asked to work with the Design Office who have experience in this field and know to anticipate the problems they may encounter.“

Where do you add value by comparison with your competitors ?

“We are more flexible, we can customise the material itself, we work on bespoke solutions and support. We cover a range of solutions, not just EMI and thermal. We are a hybrid solution, in between the large and small players. We have the production capacity of larger companies and the flexibility, reactivity and closeness of the smaller ones.“

Can you give me an example of one of your clients’ cases ?

“We have a Telecomms client, we got involved at the end of the design process, and offered them a metal joint solution which was integrated into their 3D simulation.

The purpose of our intervention was that two surfaces were in good contact to electromagnetically screen the board.

During our support the client discovered some thermal problems on their boards, and also some localised EMI problems. So we intervened on their absorbents to isolate a component which was particularly susceptible to interference.

We then attended to the thermal aspects. We started off with a putty-type thermal product; this was already an improvement from the thermal pad type of material. The thermal pad would have had to cover such a large area that it would have caused considerable tightening stresses. To better meet their needs, we innovated by associating two layers of material. The lower layer was a typically flexible thermal pad , and the upper layer, in contact with the electronic components, offered a flexibility of contact to avoid damaging the electronics. In this way, we were able to solve all their problems.

Today, the design is stable and in pre-production.”