Hello everyone,

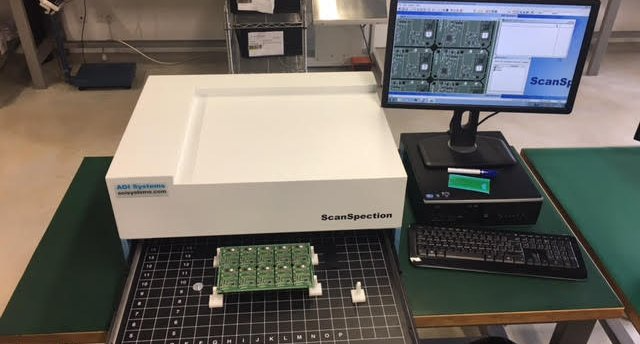

We are pleased to write to you today to present the first control machine, with the well-known name of AOI, machine allowing us to check the correct position and the correct polarity of the components on our boards.

Hello everyone,

We are pleased to write to you today to present the first control machine, with the well-known name of AOI, machine allowing us to check the correct position and the correct polarity of the components on our boards.

An indispensable machine for guaranteed quality, but how does it work ?

The AOI or Automatic Optic Inspection is a scanner with an optical camera that can be pointed at the top and sides of the board so our technicians can check that the components have kept a good polarity, the correct placement in X and Y through a laser components as well as checking their presence.

Once the board comes out of the oven, a technician sets the machine and it automatically checks the board.

Always in a process of reduced deadlines, each minute is optimized in order to be able to send all the boards in time and without neglecting the quality.

The result is a reliable, high-quality board that is quickly manufactured and shipped as quickly as possible. And most importantly, a merchandise return rate of less than 1%.

We hope that this section to discover our machines, you like and that you take a liking to better understand the process of making fast boards.

See you next week,

EMSPROTO Team