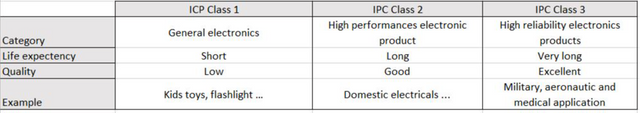

What is the IPC class :

The IPC

Class correspond to a norm that qualify manufacturing and assembly of an

electronic board, from IPC Class 1 to IPC Class 3.

This norm

is generalized as a global one. For example, the IPC-A-610 is declined under 3

norms, the IPC Class 1, 2 and 3. These ones are rank from the better (IPC class

3), to the less good (IPC class 1).

Why referring our manufacturing quality according to this norm :

The reason

that justify the IPC standard use is defined by the quality factor that is

provided with the final product.

This

standard insures a quality level of the final work, based on specific and

demanding criteria. The more the norm is demanding, the less the default

acceptance level fall down.

As an

example, the IPC Class 3 ensure a very long life expectancy of the electronic

board in very hard climatic conditions.

Concrete definition of the IPC Standard :

Class 1 : General electronic products

This

standard corresponding to low price electronics board with short life span.

Typically, some products like kids electronic toys, flashlights, TV remotes …

can be find in this category.

Class 2 : Specific use electronic products

The class 2

is one the most generalised for the manufacturing and the assembly of

electronic board worldwide. EMSFactory minimum quality at the end of

production lines is based on this norm. With this quality level, the life

expectancy of electronic boards is insuring to be as long as possible and the

quality level is fixed to an optimal level. According to the quality of the IPC

2, some electronic products as smartphones, computers and some domestic

electrical can be associated with it.

Class 3 : High reliability electronic products

The IPC

Class 3 is linked with high quality of manufacturing and assembly of electronic

boards. It is one of the highest electronic quality worldwide. The IPC Class 2

fields of application concern the aeronautics, spatial and military sectors.

The life expectancy of these is defined to be as long as possible with the

highest quality that the electronic manufacturing sector can offer.

Why choose the IPC Class 2 as base quality for its products :

The

reliability and quality level that represents the IPC Class 2 ensures that the

finished product is able to resist; for prototyping applications and small

product series; to some test and specific uses. This norm is also use because

it ensures a control and a quality level at the end of production lines that

can meet deadlines of the project.

Brief, Why choose the IPC Class 2 for your electronics boards ?

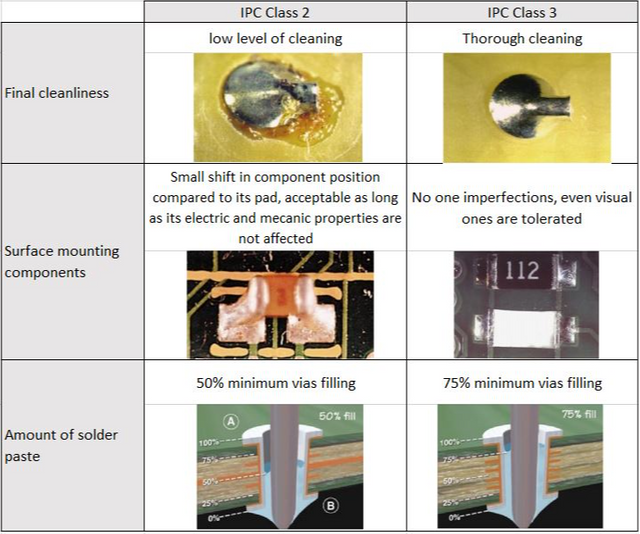

- Conception : pretty simple conception, that require not much constraints, and can be realised pretty easily

- Manufacturing : no much constraints assembly but still with a quality that ensures an optimal life expectancy

- Final check and inspection : some imperfections that don’t have much influence on the board functioning can be accepted on the control step, regarding to respect limits that the IPC standard impose

Why choose the IPC Class 3 for the manufacturing of your electronic board

The IPC

Class 3 ensures a quality of excellence in manufacturing and assembly fields of

electronics boards. This one can be choose for some constrains of solidity and

reliability that are obligatory for the project. The assembly and verification

process that come with this norm requires more time than IPC Class 2 process,

because of constrains link with tolerance of the manufacturing and control

process.

Brief, Why choose the IPC Class 2 instead of the IPC Class 3 for your electronics boards ?

- Conception : much longer conception time that requires to take under consideration as electromagnetics perturbation for example

- Manufacturing : long time assembly because of constrains link with the soldering paste application and components placements

- Final check and inspection : very few of imperfections are considered as acceptable by the IPC Class 3, that can lead to some adjustments on the final product that extend the manufacturing deadlines

Example of differences between IPC Class 2 and IPC Class 3:

Service proposed by EMS Factory :

EMS Factory

propose to buy by default an IPC Class 2 electronic boards assembly, that can suits

all needs. For more specific and demanding use of the product, that corresponds

to a better quality, EMS Factory offers too manufacturing and assembly of IPC

Class 3 electronic boards. This standard requires a particular step of control,

that is realized by ourselves at the end of the manufacturing process as well

as a report attesting to this quality, which is realized by the ILED quality

lab (https://iled-lab.fr/).