Why are PCBs and some components sensitive to moisture?

Printed

circuit boards (PCBs), or certain components, are made of porous materials

(fibreglass, ceramic, etc.) and can store moisture.

This

moisture is vaporised during reflow due to the rapid temperature rise above 217

°C. This mechanical expansion causes delamination of the component (cracks) or

PCB. This expansion is amplified by the fact that the temperatures reached are

higher than the glass transition temperature of the plastic materials: the

point at which its expansion coefficient increases strongly.

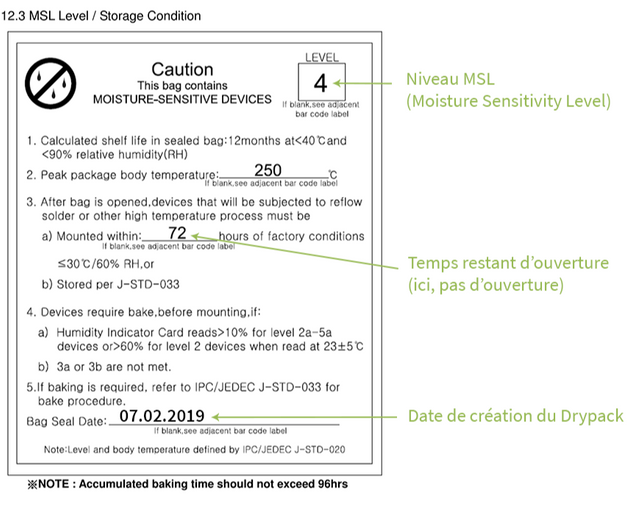

How does the MSL (moisture sensitivity level) indicator work?

Moisture

sensitive components are identified by manufacturers by a level called MSL

(Moisture Sensitivity Level) which ranges from 2 to 6. More the level is high,

the more sensitive the component. The components most often concerned are BGAs,

LEDs, Modules...

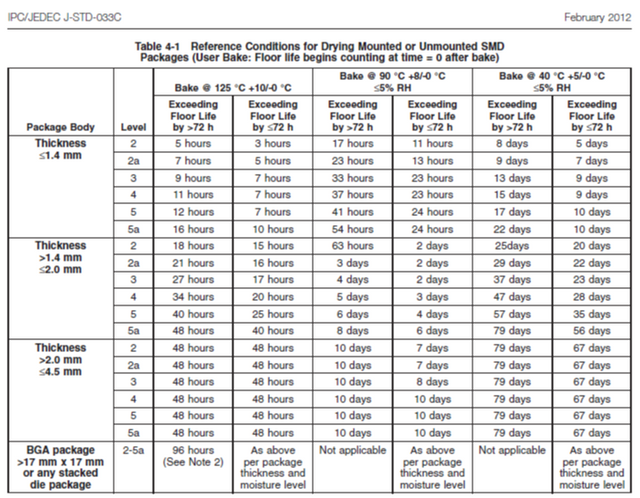

The JEDEC standard J-STD-033C regulates the MSL (Moisture Sensitivity Level), the backing time and the floor life. This is the maximum time between the opening of the Drypack and the reflow of the component.

In order to

avoid any moisture regrowth, we store PCBs and sensitive components in an

equipment called: dry cabinet.

Firstly, this

equipment allows us to store PCBs after drying if they are not soldered within

24 hours.

Then, it

also allows to store MSL (Moisture Sensitivity Level) components when they are

unpacked from their Drypack protecting them from humidity.

Finally, the boards, at the end of the SMD assembly, are stored in a dry cabinet if the repair or soldering of the through-holes is not carried out during the day.

Do not hesitate to contact our customer service via chat or e-mail: sales@emsfactory.com for all requests!